- Home

-

All Category

- Single Core Flexible Cables

- Multicore Flexible Cables

- Building Management & Security System Cables

- Fire Survival Cables

- Industrial Automation Cables

- Bus System Cables

- Instrumentation Cables

- Thermocouple & Compensating Cables

- PUR Cables

- Signal & Control Cables

- Rubber Cables

- Silicone Cables

- High Temperature Cables

- Solar Cables

- Marine & Offshore Cables

- Military, Aerospace & Defence Cables

- Under Water Cables

- Composite & Hybrid Cables

- Company Profiles

- Contact Us

Sourcing & Procurement

Strategic sourcing and rigorous quality control ensure consistent, high-performance materials for every cable we manufacture.

Export Licenses

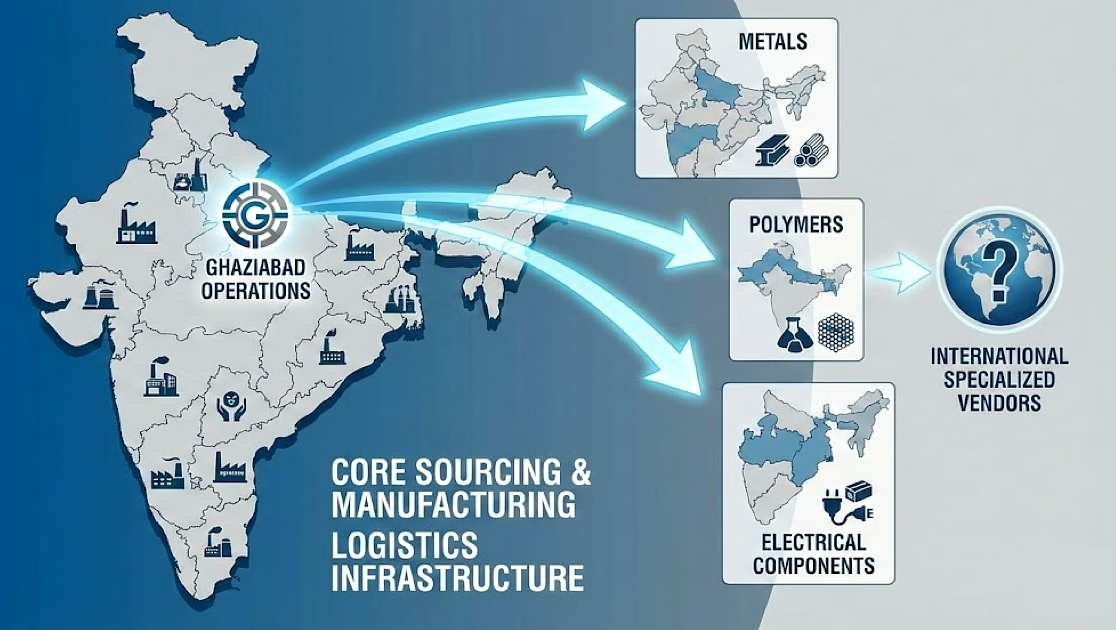

• Core sourcing and manufacturing operations are based in Ghaziabad, Uttar Pradesh, India, with access to established industrial ecosystems and logistics infrastructure.

• Raw materials and key inputs are procured from qualified suppliers across major industrial regions of India known for metals, polymers, and electrical components.

• Where specific performance or compliance requirements demand, selected inputs can be sourced from specialised domestic or international vendors after qualification.

Supplier Relationships

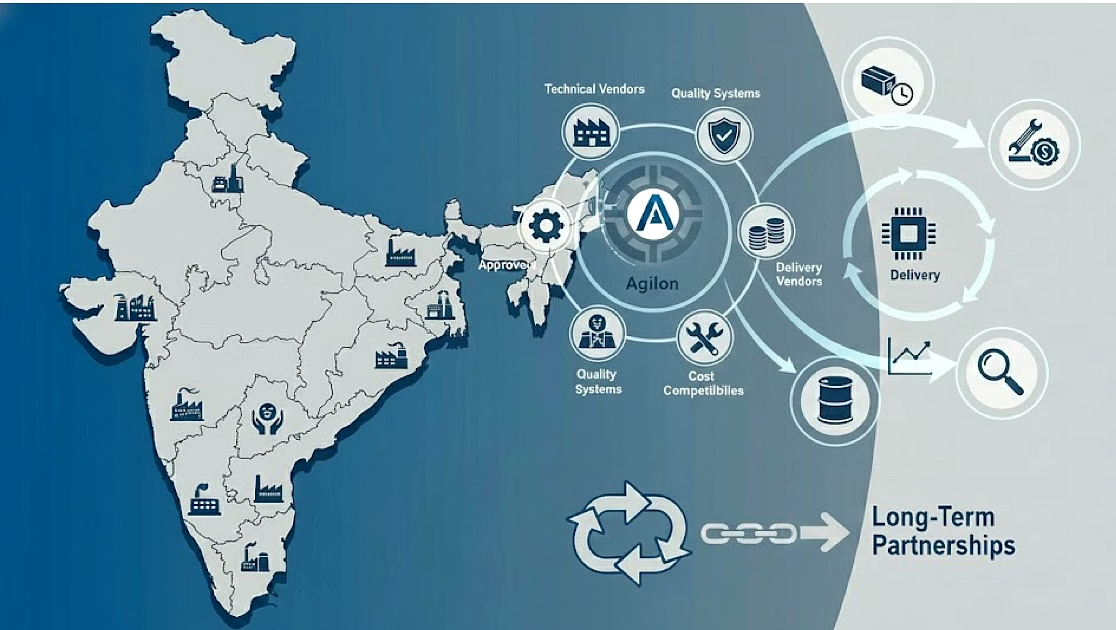

• Agilon works with a network of approved vendors that are evaluated for technical capability, quality systems, delivery reliability, and cost competitiveness.

• Suppliers are periodically reviewed based on performance, documentation, consistency, and responsiveness to new product and project requirements.

• Long‑term partnerships are encouraged so that materials used remain consistent over time.

Raw Material Selection

• Only materials that meet stringent electrical, mechanical, and environmental criteria are selected for conductors, insulation, shielding, armouring, and sheathing.

• Copper and other conductor materials are chosen for conductivity and reliability; insulation and jacket compounds are selected for properties such as flame performance, temperature resistance, flexibility, and environmental behaviour, depending on the application.

• For specialised wires & cables, tailored compounds and constructions are used to withstand heat, fire, moisture, chemicals, and mechanical stress in demanding conditions.

Quality Control Process

• All incoming raw materials from suppliers undergo checks as per defined quality plans before being released to production.

• During manufacturing, in‑process inspections monitor dimensions, concentricity, resistance, insulation integrity, and other critical parameters for each wires & cable family.

• Finished wires & cables are subjected to routine tests and, where applicable, type tests to validate electrical, mechanical, and physical performance against relevant standards and application requirements.

• Test results are documented, and routine test certificates can be provided with each batch, supporting both domestic compliance and export documentation needs.